传统的压痕机是不是只能淘汰,只能人工操作!?

发布人:管理者 发布时间:2021-04-07你了解的手动压痕机是不是还停留在传统人工放料的环节?新设备出来发现虽然全自动但是价格太贵!老设备也只能搁置!

手动压痕机

自动压痕机

适用范围:适用于各类坑纸、瓦楞、胶片、海棉、灰板、吊牌的模切加工。

产品简介:

1.采用PLC控制,触摸屏人机界面,参数式设置及故障显示;

2.前档及边档可依纸张版面大小自由调整、调整方便;

3.送纸台备有补台装置,可连续操作不停机;

4.光电多重检视,入纸收纸均采用真空吸盘,无压痕;

5.收纸台备有板车,操作容易、省力,亦可加装插纸计算器;

6.飞达部有轨道装置,作版时可自由分开,方便作版;

Automatic die cutting machine:

Scope of application: suitable for all kinds of pit paper, corrugated, film, sponge, ash board, tag die cutting processing.

Product introduction:

1. PLC control, touch screen interface, parameter setting and fault display;

2. The front and side files can be adjusted freely according to the size of the paper layout for convenient adjustment;

3. The paper feeding table is equipped with a replenishing device, which can operate continuously without stopping the machine;

4. Photoelectric multiple inspection, paper in and paper out all adopt vacuum sucker, no indentation;

5. The paper receiving platform is equipped with a pallet, which is easy to operate and labor-saving, and can also be equipped with a paper calculator;

6. Feida part of the track device, version can be separated freely, convenient for version;

那么问题来了!

1:手动的可以清废、切线,但是速度慢、不安全,还需要养人工,一台机器一个人

2:自动的可以切线确不方便清废,还得养人工,速度是上去了,但总归在人操作的哪部分就是慢下来了

皇盈自动化设备有限公司就在全自动模切很贵,充分利用原有压痕机不浪费的基础上研发了加装机械手的装置,上料、下料、清废等一系列功能全有

智能模切压痕清废机械手

适用范围:各类大小规格的纸张的模切,包括且不限于 80g书纸、120g~157g双铜 纸、200 g~500g白板纸、600g~1200g灰板纸、瓦楞纸、0.2MM以上的胶片等。

产品简介:

1.采用PLC控制,触摸屏人机界面,参数式设置及故障显示;

2.推规使用伺服电机,精度+/-0.2mm;

3.调试只需十分钟,操作安全简单,单人可同时看4-5台机;

4.上料、模切、清废、收料,四工位三轴设计,节省人力及存储空间;

5.最大速度达1500-1800张/小时;

Intelligent die cutting indentation scrapping manipulator

Scope of application:

Suitable for die-cutting of paper of various specifications, including but not limited to 80g book paper, 120g-157g double copper paper, 200g-500g white board paper, 600g-1200g grey board paper, corrugated paper and film sheets (over 0.2mm).

Product introduction:

Using PLC control, touch screen and man-machine interface, with parameter setting and fault display.

b. Using servo motor, the error range is +/-0.2mm.

c. It needs only 10 minutes to set up the machine. The operation is safe and simple. One person can operate 4-5 sets of machines at the same time.

d. Paper loading, die cutting, waste chip removal and material collection achieve three-axis design, which saves labor cost and space.

e. The maximum working speed can be up to 1500-1800 pcs of paper per hour.

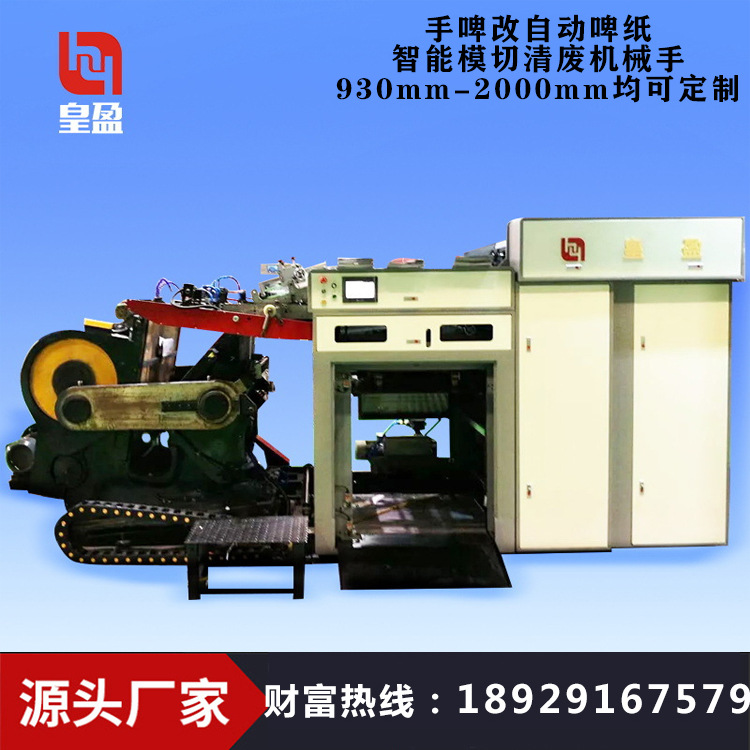

压痕模切清废机械手

单机智能压痕清废机械手详图

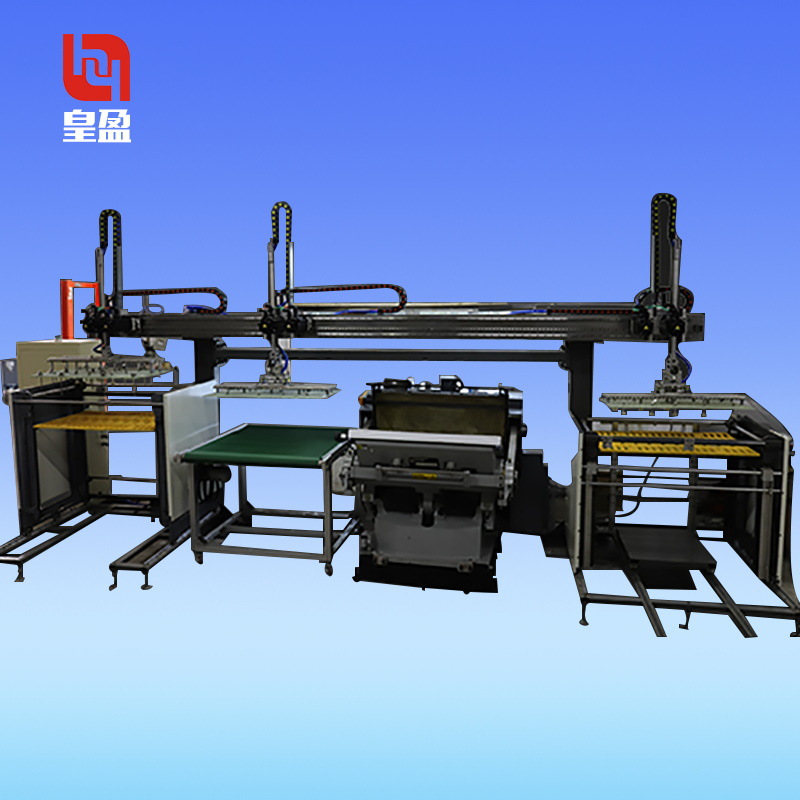

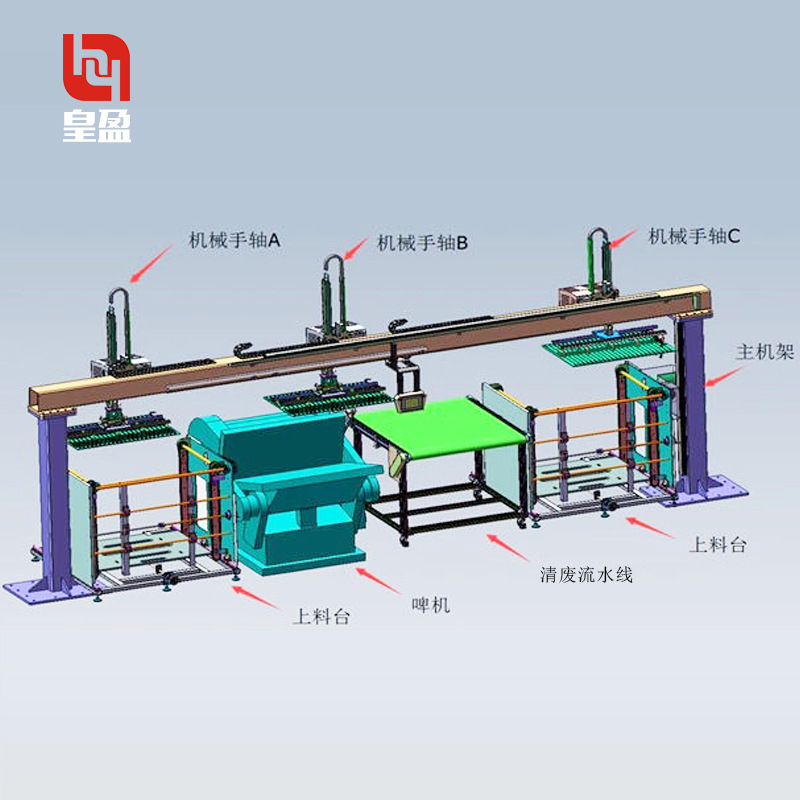

多工位智能压痕清废机械手详图

多工位智能压痕清废机械手详图

您说这样的智能压痕清废模切机械手实用不实用??

皇盈为广大纸类印后客户提供的压痕机清废机械手优质方案,希望能充分解决大家的人工,效率等问题,实现双赢的目的!

在线客服

在线客服